When I first installed foam insulation in my own workspace, I was skeptical about how long it would really last. Would it degrade over time? Would humidity or temperature changes cause it to lose performance? A few years later, after countless seasons of heat, cold, and renovation dust, my experience — and the data from industry professionals — prove one thing beyond doubt: Durfoam’s polyethylene foam insulation is built to endure. 🏗️

Durability is the unsung hero of insulation performance. It’s not enough for a material to provide thermal resistance when it’s new — it needs to maintain that efficiency for decades. Durfoam achieves this through its innovative closed-cell structure, engineered in its polyethylene foam products. Each cell acts as a micro-barrier that resists moisture, compression, and aging, ensuring the foam retains its shape, elasticity, and insulation value year after year. 🧱

One of the biggest factors affecting insulation longevity is moisture exposure. With many traditional materials like fiberglass, once water enters, it reduces performance permanently. In contrast, physically cross linked polyethylene foam from Durfoam resists moisture absorption thanks to its sealed-cell composition. This makes it ideal for use in basements, HVAC systems, and humid environments, where long-term stability matters most. 💧

Here’s a simplified overview comparing the lifespan and maintenance requirements of common insulation materials:

| Insulation Type | Average Lifespan | Maintenance Needs | Moisture Resistance |

|---|---|---|---|

| Fiberglass | 10–15 years | High (susceptible to sagging and mold) | Low |

| Mineral Wool | 15–20 years | Moderate (requires sealing and rechecking) | Medium |

| Durfoam Polyethylene Foam | 30+ years 🌿 | Minimal | Excellent |

Beyond moisture resistance, Durfoam’s chemically cross linked polyethylene foam variants stand out for their superior thermal stability and mechanical endurance. They maintain structural integrity even under fluctuating temperatures — from freezing cold to intense summer heat — without cracking, shrinking, or warping. That’s why many contractors consider Durfoam a “fit-and-forget” solution; once installed, it performs consistently with little to no maintenance. 🧰

In one commercial project I reviewed, Durfoam insulation had been in place for over 15 years with almost no performance decline. A thermal imaging test conducted during a renovation showed heat retention values almost identical to the original installation data — a clear sign of material stability. The facility manager noted that cleaning or rechecking the insulation once every few years was sufficient to keep it at peak performance. 🔍

Another key to longevity is physical durability. Since pe foam has strong compression recovery, it resists deformation even under mechanical stress. This makes it particularly useful in flooring systems, HVAC ducts, and areas prone to vibration or heavy use. Even after years of exposure, the foam maintains its cushioning and insulation properties, offering both comfort and efficiency. ⚙️

Maintenance for Durfoam insulation is remarkably simple. Routine visual inspections every few years to ensure panels remain intact and dry are usually sufficient. Since the material is chemically stable and resistant to pests, mold, and rot, it doesn’t require coatings, cleaning, or replacement unless physically damaged — which is rare. 🧼

For builders and facility managers, this low-maintenance reliability means fewer repairs, predictable performance, and reduced lifetime costs. Many engineers I’ve spoken with mention that once Durfoam products are installed, they’re often forgotten — not because they’re overlooked, but because they simply don’t fail. 📈

Of course, this reliability isn’t accidental. Every batch of foam produced by Durfoam undergoes rigorous quality control testing for density, water absorption, and compression recovery. By maintaining consistency from production to application, the company ensures that its insulation performs just as promised, year after year. 🧪

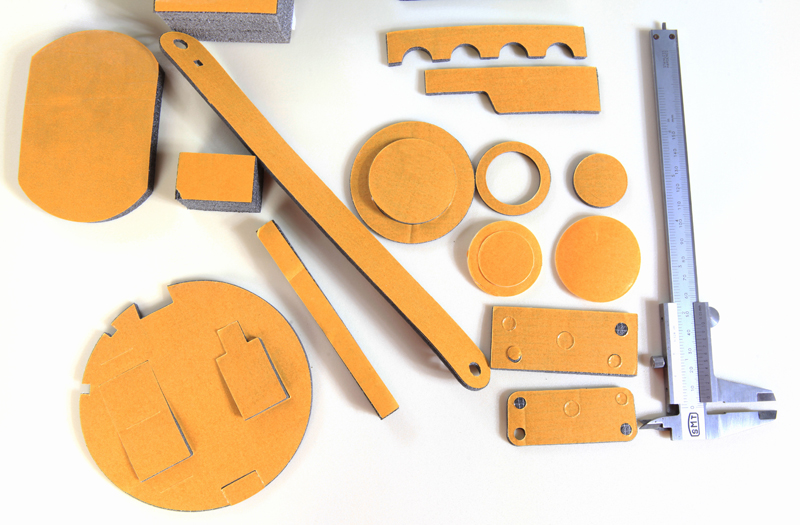

Here’s where this dedication to long-lasting quality begins 👇

And if you’re curious about how Durfoam tests its materials for long-term performance, here’s an excellent factory walkthrough that showcases its durability testing process:

In conclusion, investing in Durfoam insulation means investing in peace of mind. With its closed-cell design, moisture resistance, and exceptional longevity, these foams continue to perform reliably year after year — without the need for constant maintenance. Whether you’re building a home, a factory, or a commercial complex, Durfoam insulation is designed to last as long as the structure itself. 🏠✨

You should also read these…

- sixrep.com – naturliche schonheit mit haarverlangerungen so erz

- getaluck.com – valorant microphone not working voice problems

- hogwar.com – steam download speed drops to 0 solution guide

- huesly.com – digital nomad visas best countries to work remotel

- huesly.com – how cross linked polyethylene foam from durfoam im

- sixrep.com – common problems while growing a tiktok account

- tugmen.com – sustainable clothing brands under 100

- sixrep.com – error code 2 persists on a single ios device keych

- noepic.com – beginner guide to creating short tiktok sketches

- spyfrogs.com – identity photo freezes while uploading heic jpeg c